LSF structures are mainly constructed using screws or nuts & bolts connections. These structures comprise three main components i.e. cold rolled sheets for the structure, gypsum boards for the interior walls, and cement boards for the exterior. Soundproof and heat insulation layers are placed inside the walls. These buildings are built with C or U-type galvanized sheets in various dimensions and thicknesses of 0.6 to 1.5 mm.

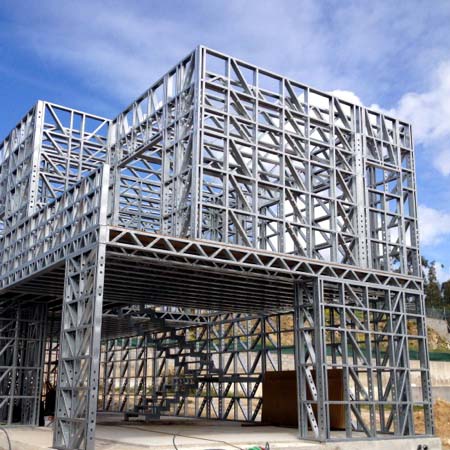

One of the main advantages of light steel framing is its versatility and the range of building types for which it can be used. Applications of light steel framing range from low-rise housing to multi-story, multi-occupancy developments, including panelized structural frames, external infill walling systems, and fully finished offsite modular construction. The range of building types is indicated by the projects shown in Figures 1 to 4.

Forms of construction

Light steel framing comprises galvanized cold-formed C sections of 70mm to 100mm depth in the wall panels, and 150mm to 300mm deep C sections or lattice joists in the floors. Spans of up to 6m can be achieved, which can eliminate internal load-bearing walls and therefore leads to flexibility in internal space planning.

The prefabricated wall panels are typically story-height (ie 2.7m to 3.2m) and up to 8m long, depending on transportation and lifting.

A house can be constructed from as little as 12 wall panels and up to four houses or large apartments can be delivered per lorry. The floors can be installed in the form of prefabricated floor cassettes, or as individual joists. A typical light steel project during construction is shown in Figure 5.

The option to use composite floor slabs supported by light steel walls (as shown in Figure 6) is popular in some sectors. In this case, the floor slab is typically 150mm to 180mm deep using profiled steel decking with in-situ concrete and spans up to 5.5m when propped temporarily during construction. Not only is the self-weight half of that of a concrete flat slab but it is shallower and provides for the routing of ducts suspended from the decking.

Both joisted and composite floors often use slim floor beams that are integrated within the floor zone to create more open-plan space, which is particularly useful in care homes and in lobby areas. Concrete and steel stairs are generally delivered as part of the light steel package and are integrated into the Building Information Model (BIM) provided by the light steel supplier.

The structural performance of cold-formed sections enable their use in a wide variety of applications. A light steel C section of only 1.5mm thickness can support up to 50kN in compression. Structural bracing is integrated into the walls for stability so that medium-rise buildings do not require additional cores. Efficient design solutions are achieved by selecting the steel thickness and configuration of sections to suit the specific loading conditions.

Urban developments

The benefits of offsite manufacture and of light steel framing in particular come to the fore in urban residential projects that often involve a mixture of townhouses and larger apartment buildings. Figure 7 shows a city center hotel using light steel frame construction. The advantages that are sought by the client and contractor are:

- A packaged construction system in which all the structural components are designed, delivered, and installed by one supplier.

- An integrated BIM model is prepared by the supplier, which links to the architect’s model and can be used and added to by the main contractor and client.

- Minimizing deliveries and storage space in congested inner-city sites. This is achieved by ‘just in time delivery to the site. Panels are color-coded or labeled so they can be easily identified.

- Minimizing loads on the foundations and any supporting structure, and also when constructing over tunnels or on brownfield sites or rooftop extensions.

- A versatile construction system that is efficient for housing and for residential buildings up to 10-story buildings.

- High quality in terms of geometrical accuracy and freedom from any long-term movements due to creep and shrinkage, eliminating callbacks.

- Good sustainability rating based on a range of environmental criteria. Light steel framing can be designed for low U-values and scores A+ or A under the BRE Green Guide. All steel components can be recycled and building extensions can be made easily in the future.

Mixed-use developments

Mixed-use developments generally comprise commercial or retail space at the lower levels and residential units above. A good example is where three- or four-story housing is constructed over retail space, such as supermarkets in urban areas. The mixed nature of the project may be required for planning reasons or to maximize the return from land use.

The key requirement is a lightweight super-structure with the ability to span between the transfer beams and to be sufficiently robust to tolerate differential deflections of the supports. Light steel framing has proved to be the perfect solution as it weighs less than 100kg/m2 per floor while achieving spans of up to 6m between beams.

Building Information Modelling (BIM)

The light steel framing industry is leading the way in BIM, which is essential to the manufacturing process and eliminates problems on-site, especially with interfaces to other components. In light steel framing, a 3D BIM model of the structure of the building is created in IFC format and is shared with the project architect during the formative stages of design.

It is important that the light steel supplier is appointed early in order to be able to maximize the benefits of an integrated BIM model (see Figure 8).

From this, the light steel supplier produces panel drawings for their manufacture and also for the other components, such as steel beams and stair units, which are integrated into the model. This enables a consistent geometry and interfaces with other key parts of the building, such as façades and services. Clashes are identified and solved at this stage. The main contractor or project architect would often take on the BIM model and manage subsequent updates so that it is available to the client and facilities manager.

No comment